Our Product Responsibility Policy

Building technology for customers’ high-quality development

Haitian International focuses on product safety and continuous improvement of product quality, and wins customer satisfaction through the research and development of green and innovative technologies, comprehensive quality management system, and high-quality services. We control our products effectively at every stage from customer’s demand to production and shipment, ensuring that product quality management is effectively implemented. With continuous growth of our business, we are building a green manufacturing system with high efficiency, energy saving and low-carbon, and have passed the certification of “Low-Carbon Product Supplier”. Some of our series are listed in the National Catalogue for the Recommendation on Industrial Energy-Saving Technology and Equipment.

Clean Technology

Product Quality

Service Quality

Intellectual Property Protection

Clean Technology

Haitian International actively responds to the national “carbon peak in 2030 and carbon neutrality in 2060” strategies, and is committed to continuously meeting the increasing demand from customers for environmentally friendly products.

The automotive industry is one of the most extensive markets for injection molding applications. In recent years, with the rapid popularization of electric vehicles (EVs), the application of our products in the EV industry has become the key driver of business growth. Haitian International considers the EV industry and the clean and low-carbon transformation of traditional automotive manufacturers as pivotal strategic opportunities. The company actively deploys solutions for industrial automation, lightweight materials, recyclable materials, and battery logistics, accelerating the application of technological achievements in the EV value chain, and continuously empowering the sustainable transformation and upgrading of the automotive industry.

Furthermore, the company will stay updated with technological developments in various industries, seize new opportunities brought by technological advancements, and continuously meet the demand for sustainable development across different sectors. This will enable the company to lead the value chain towards a greener and cleaner future while achieving sustainable corporate development.

Haitian International will continue to increase its investment in automation, digitalization, and clean technologies in the future. Each year, the company will review and allocate appropriate funds for technological innovations in automation and energy-saving measures of the product portfolio. By providing advanced intelligent green solutions, The company aims to assist customers in improving production efficiency, reducing energy consumption, and minimizing environmental impact while meeting the demands of sustainable development for both the company and its customers. Additionally, the company will closely monitor technology trends throughout the value chain to ensure the consistency and competitiveness of our technology and products with market demands. Through continuous investment and innovation, we will drive technological advancements, lead industry development, and provide customers with exceptional automation and clean solutions.

Certified as the “Low-Carbon Product Supplier” by the China Electronic Energy Saving Technology Association1

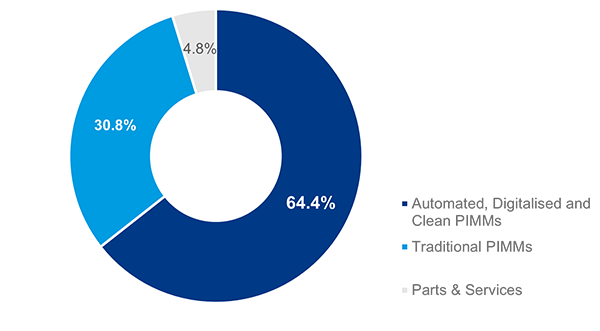

64.4%

Revenue from the Automated, Digitalised and Clean PIMMs accounted for 64.4% of the total revenue2

28,898 kW

The total installed capacity of rooftop photovoltaic (PV) projects has reached 28,898 kW by the end of 20233

.

Sales mix by product type in 2023

1: As we have been sticking to the sustainable development strategy, and developing energy-saving and consumption-reducing technology to reduce the energy consumption of our products, we were certified as the “Low-Carbon Product Supplier” by the China Electronic Energy Saving Technology Association in 2021. Our MA, JU, VE, ZE and JE series PIMMs have been certified as the “Key Energy-Saving Products for Promotion in Ningbo”. Among them, our MA and VE series PIMMs have received the national carbon label certification, making us the first batch of domestic injection moulding equipment enterprises to obtain the “carbon label”. Three-phase REPMSMs, listed in the national “Energy-Saving Products for Public-Interest Project” – the Catalogue for the Promotion of High-Efficiency Motors, are applied to all our products, saving an average of 50% energy compared with that of traditional asynchronous motors. In addition, we, as a responsible industry leader to build an efficient, energy-saving and low-carbon green manufacturing system, were designated as the drafter by the China Plastics Machinery Industry Association to formulate the Technical Regulation for Carbon Label Evaluation for Rubber and Plastic Injection Moulding Machine (《橡胶塑料注射成型机碳标签评价技术规范》). And we, as the president of the association, actively drive the formulation of relevant national standards.

2: The full range of PIMMs product series under Haitian International, including the MA series, JU series, and Zhafir electrical PIMMs series, have been fully integrated with intelligent and automation technologies starting from the third generation (G3) models. Through multiple innovations in software and hardware, We assist our clients in achieving manufacturing automation and digital management in their production processes.

The MOTION PLUS intelligent motion control platform, which comes as standard with all PIMMs products, enables the machine to perform precise operations under high precision and various operating conditions, ensuring stability and consistency in product quality. The system also features multi-stage adjustable dynamic control capabilities, allowing flexible production configuration and process optimization to meet diverse production requirements of our customers. The full range of PIMMs product are equipped with open integration capabilities, supporting real-time information sharing and command transmission with peripheral equipment and automation units. This enables factory automation and process optimization, enhancing production efficiency and flexibility. The servo-hydraulic PIMMs are also equipped with automatic mold adjustment and automatic purging functions, which can reduce production downtime and minimize errors caused by manual operations. In addition, the Factory Cloud 2.0 software system, which is standard on all PIMMs products, can meet clients’ demands for digital factory management. Clients can achieve real-time online monitoring and efficient operations through the mobile app. The latest fifth-generation (G5) models of all PIMMs products are equipped with the energy management module, which continuously monitors and records energy consumption data of the entire machine, specific components, and various production stages. This provides users with a basis for energy management and optimization decisions.

3: By the end of 2023, the total installed capacity of rooftop PV at Tongtu Road Plant was 22,698 kW, and the total installed capacity at the South China Plant was 6,200 kW.

CREATE SOLUTIONS FOR LIGHTWEIGHT, BIODEGRADABLE, AND RECYCLABLE MATERIALS

With the popularity of new energy vehicles, the demand for lightweight parts has put forward more stringent requirements on the injection moulding process of automotive parts, and the G5 JU series two-platen injection moulding machine adopts the microfoam moulding process, which is widely used in the production of automotive interior parts. This process realizes weight reduction and significantly improves warpage and dimensional stability of the parts. In addition, the microfoam moulding process reduces clamping force, saves material, and improves production efficiency.

In the face of the environmental challenges posed by plastic pollution, it has become more and more urgent to accelerate the application of biodegradable and recyclable materials, and the MA series of high-speed injection moulding machines are capable of producing products that comply with the international biodegradable packaging material standards of EN13432/ASTM D6400. For example, the PLA material, which has a biodegradation rate of more than 90%, is utilized in the production of high rigidity, strong toughness, heat-resistant food containers, plates, trays, cups, etc. The G5 ZE series of electric injection moulding machines can utilize the recycled plastics of ABS and PP, which are widely utilized in the consumer electronics industry, achieving clean recycling and renewal of plastic products and empowering the development of the circular economy.

G5 MODELS: ACCELARATING ENERGY SAVING AND INTELLIGENT INNOVATION

With the goal of making our products more energy efficient and intelligent, Haitian International has developed the fifth generation (G5) machines by applying clean technologies to reduce the energy consumption, improve the operating efficiency and reduce the residue of harmful substances, enabling the overall operating energy consumption of the G5 hydraulic machines to be reduced by more than 20%-40% compared with the corresponding third generation models. Meanwhile, all series are equipped with the “Go Factory 2.0” digital and intelligent management software and open integration functions, which can maximize customers’ one-stop demand for automated and digital production.

- In order to reduce energy consumption, we have optimised the hydraulic transmission system of the G5 hydraulic machine and improved its transmission efficiency, with mathematical modelling, overall simulation as well as adoption of digital twin technology in designing powertrains and precision transmission mechanisms.

- Some of the key motion actuators are utilising “electric instead of liquid” as standard, which significantly improves the energy efficiency of the G5 hydraulic machines.

- The G5 hydraulic machines are equipped with energy-saving water valves and quick-release insulation devices, which also further exploit the energy-saving potential in the heating and cooling phases.

- The energy management module, which is the standard configuration on all G5 models, continuously monitors and records the energy consumption data for the whole machine, individual parts and individual production stages, providing users with the most detailed basis for energy management and optimisation decisions.

- In terms of execution efficiency optimisation, all G5 models are equipped with reinforced plasticising components as standard, reducing machine running time and increasing operational efficiency. The bimetallic reinforced structure has more than doubled the effective life of the plasticising unit compared to the previous generation models, extending the machine’s trouble-free running time and thus improving the yield.

- Intelligent lubrication based on predictive maintenance control is standard across all G5 models, effectively preventing damage to the machinery, reducing the generation of waste fluids, and reducing the probability of unscheduled machine downtime.

- Energy saving water valves for the hydraulic system are also equipped as standard, which further reduce the demand for the total amount of cooling water of the customer’s fleet of G5 hydraulic machines and optimise the utilisation of the customer’s water circulation system in the plant.

Product Quality

In strict compliance with the Product Quality Law of the People’s Republic of China and relevant laws and regulations, the Group has established a comprehensive system for product quality control. Through the product quality control and tracking in the processes of parts procurement, processing and assembly, product shipment, finished product testing, and installation and commissioning, the product quality management responsibilities are effectively implemented. We have also formulated the Inspection and Test Control Procedure to monitor and measure product attributes at all stages from raw material procurement, metal processing to finished product shipment, and keep strict records for the related information, to ensure that product manufacturing meets specifications and requirements.

Service Quality

We have a sound communication and cooperation mechanism with our customers. Through telephone, email, online video conference, offline visits, invitations to negotiation and exhibitions and other online and offline communication mechanisms, we understand customers’ expectations on the Group and our products, and solve the problems that customers may encounter when using the products, to ensure the quality and safety of the products sold as well as the services provided. The Group coordinated and integrated internal resources, and set up offices for key domestic/overseas customers. With such offices, we are capable of strengthening communication with global customers and offering them business support and after-sales services in a timely and rapid manner, thereby effectively improving customer satisfaction.

Intellectual Property Protection

The Group strictly abides by the Trademark Law of the People’s Republic of China, the Patent Law of the People’s Republic of China and relevant laws and regulations, and establishes a number of systems and procedures to standardize intellectual property protection (IPP). At the same time, we have built a professional team responsible for patent application and maintenance, and registered our trademarks in over 90 countries to protect our interest in local businesses.