Haitian at Chinaplas 2024

Generation 5 in new applications

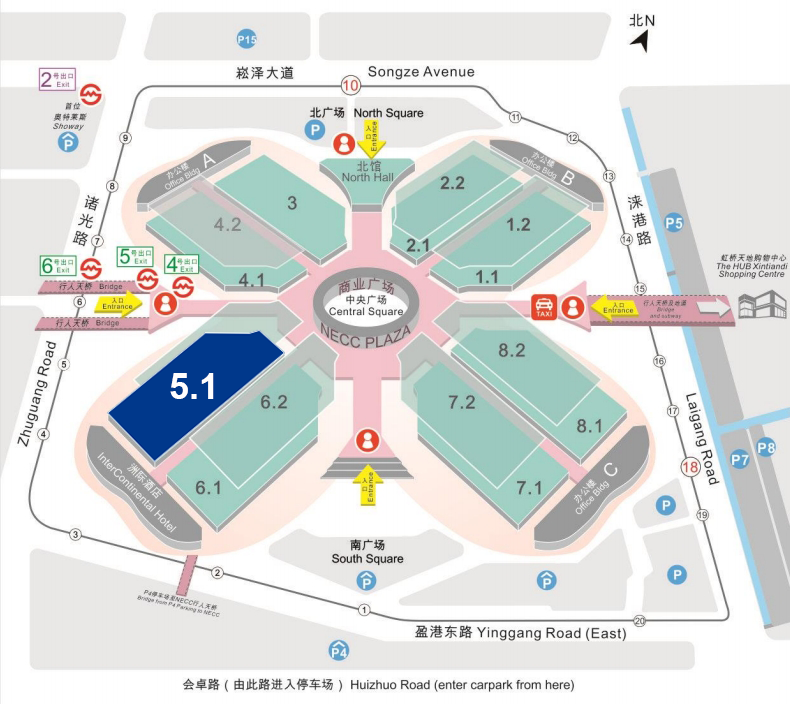

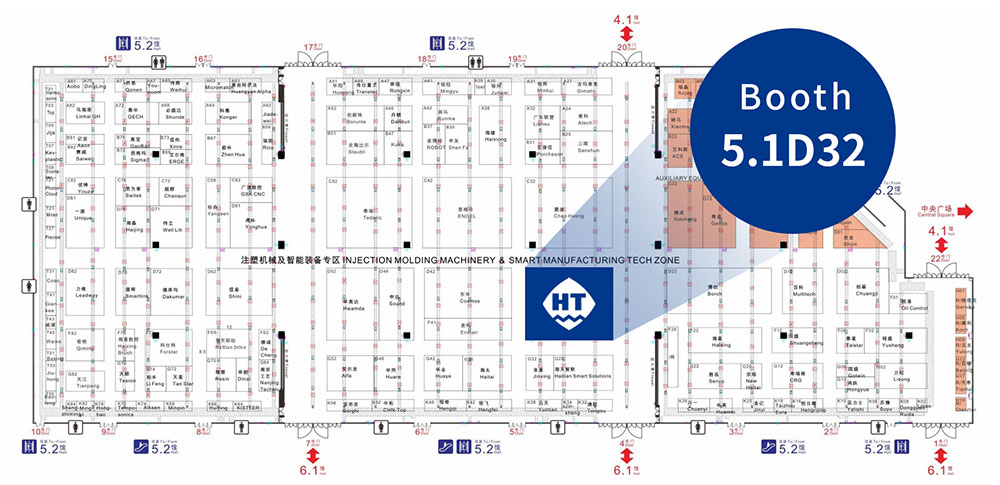

Since its market launch, the new Generation 5 has proven itself in many applications and production lines. In the meantime, we have continued to work on many production solutions and developed new, highly efficient industry solutions. We will be presenting some of them in Hall 5.1 at Chinaplas 2024.

Smart. Flexible. Sustainable

Digital intelligence is one of the keys to efficient manufacturing with a future. Energy efficiency and productivity, reliable availability and low costs, environmental compatibility and greater sustainability are important targets. The new Generation 5 from Zhafir and Haitian is geared towards these goals. The G5 combines numerous innovations at the highest level – ready for use in intelligent/networked production, with an open platform, cross-system and manufacturer-independent. In addition to a wide range of other energy-saving features, the latest generation of servo-hydraulic and servo-electric drives from Haitian Drive have been specially developed for the new series. The result: energy savings in the double-digit range with improved precision.

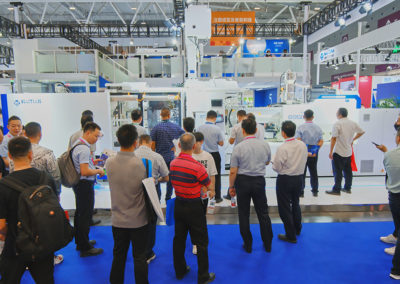

WE ARE LOOKING FORWARD TO YOU !

LIVE ON OUR BOOTH

![]()

Zhafir Venus Series

All-electric precision for cleanroom medical technology

Designed to meet the high standards of the industry, the certified VE1900V-430h with medical package brings a large range of turnkey solutions to the starting line. For clean high-cavity precision injection molding – even in unmanned production.

Application: Production takes place on a 96-cavity mold that produces a lid for blood collection tubes made of PP. The weight of the molded part is 0.7 g with a cycle time of 7.5 seconds. The integrated “Wisdom Link” automation solution enables unmanned production.

![]()

Zhafir Venus Series

Highest precision for the production of optical lenses

The VE600V-80h with LENS package is a machine specializing in optics, whose all-electric injection moulding technology is precisely tailored to the high quality requirements for lenses and whose control system enables efficient production processes.

Application: A lens for smartphone cameras is produced, injection-molded from the special material COC (cyclo-olefin copolymer). A 12-cavity mold runs with a cycle time of less than 50 seconds, the part weight is just 0.02 g.

Haitian Mars Series

World premiere of the packaging professional

The MA2100F/580 as a high-performance complete package for ultra-fast thin-wall containers + IML cell + side-entry robot. Energy-saving, stable, efficient, with top-level cycles.

Application: A 4-fold ice box with 4.2 g is produced from high-flow PP. With IML application and side-entry removal, the cycle time is 2.75 seconds.

Haitian Jupiter Series

Space-saving two-platen solution for lightweight construction

The JU5500V/3450 as a highly energy-saving and highly efficient automotive solution. Equipped with a Trexel micro-foam unit and micro-mold opening for the production of lightweight components for the automotive industry.

Application: A 1-cavity automotive part for chassis made of PP is produced with 325 g at a cycle time of 55 sec.