HAITIAN AT NPE 2024

GENERATION 5 LAUNCHES AT NPE 2024

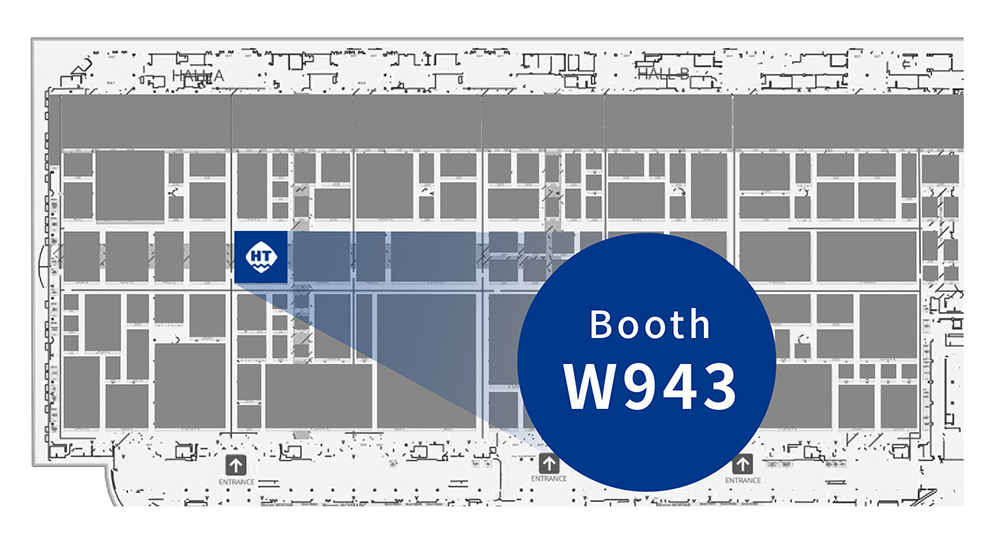

From May 6th to 10th, Haitian International will present the fifth generation of Haitian servo-hydraulic and Zhafir electric injection molding machines at NPE2024 in Orlando, Florida.

Focusing on consumer goods, automotive, and medical industries, our four solutions displayed at this exhibition emphasize energy efficiency, performance and intelligence. Through the application of multiple energy-saving technologies and high-precision controls, these solutions can achieve an energy-saving effect of 20-40% for the entire machine. Additionally, they significantly reduce the machine’s footprint and shorten cycle times.

LIVE ON OUR BOOTH

Haitian Mars Series

Energy-saving and efficient solution for consumer goods industry

Relying on the fifth generation technology and inheriting the excellent genes of the world’s best-selling servo hydraulic energy-saving injection molding technology, MA5 was launched. With smart innovation and high-efficiency energy saving, it achieves breakthroughs in all aspects of performance, perfectly meeting the manufacturing needs of the consumer goods industry for storage boxes, and delivering highly cost-effective, efficient, and stable production.

Application: Polypropylene storage containers in a SO-second cycle time for a Haitian Hilectro robot to remove.

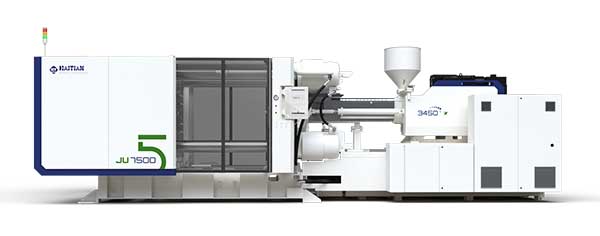

Haitian Jupiter Series

Spacing-saving solution for automotive industry

The Haitian JU fifth-generation machine features a compact structure and is equipped with multiple intelligent technologies and an electric pre-molding device, which significantly reduces energy consumption and maximizes factory space utilization, saving space. The entire system operates faster and more stably, with a dry cycle that reaches international advanced levels. The plasticizing unit has been completely redesigned and upgraded, further enhancing plasticizing performance and efficiency.

Application: An automotive panel from a polycarbonate/ ABS blend with a cycle time of 60 seconds.

![]()

Zhafir Venus Series

Clean and precise solution for medical industry

The Zhafir Medical Specialized Machine is designed to meet the high standards and cleanroom production requirements of the medical industry. The entire machine features exclusive color schemes and anti-static medical paint tailored for the medical sector, ensuring compliance with high cleanliness standards. It also significantly enhances equipment performance, enabling high-standard clean production and precise, stable injection molding, shaping a smarter, more efficient, and cleaner future for the industry, while safeguarding health and life.

Application: Medical syringe barrels are produced from Tritan copolyester in 18 seconds.

![]()

Zhafir Zeres Series

Flexible and efficient solution for medical industry

Zhafir is revolutionizing the plastics machinery industry with its fifth generation: continuous quality and efficiency improvements, digital intelligence, and sustainable solutions. These innovations shape a new intelligent manufacturing format in injection molding, setting industry benchmarks and meeting customer needs at the highest level. The new Zhafir machine generation 5 combines numerous innovations at the highest level and paves the way to a new level in intelligent production.

Application: Medical IV filters from ABS are produced in an 8-by-8-cavity stack mold in a cycle time of 18 seconds with part removal by a Haitian Hilectro robot.