Haitian Plastics Machinery Successfully Delivers Turnkey Pallet Line Project to Honsen Beverage Group and Achieves Smooth Production Start

Recently, Haitian Plastics Machinery successfully delivered three sets of HA27000/peg turnkey projects to Honsen Beverage Group, with smooth commissioning at its bases in Hangzhou, Tianjin, and Guilin. The projects enable end-to-end automated operations from raw materials to finished products, showcasing Haitian’s technological strength in the field of extra-large injection molding equipment. This milestone also marks a solid step forward in the collaboration between the two parties in the logistics equipment sector.

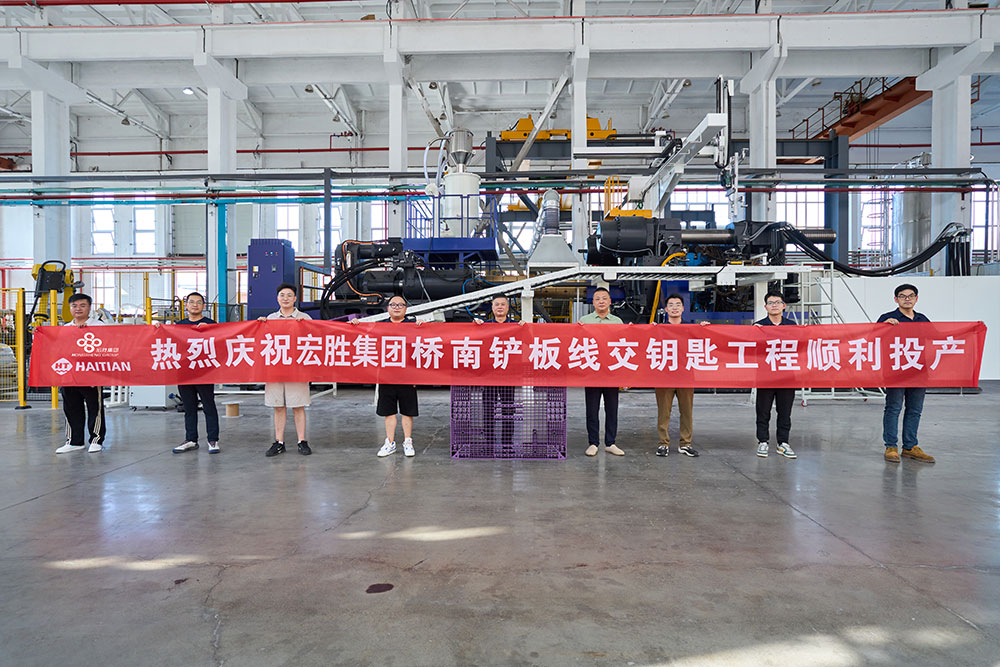

At the handover ceremonies, representatives from both sides were present, including Mr. Xu Bin, Deputy General Manager of Haitian’s Global Industry Line; Mr. Yu Feng, Manager of the Logistics Industry Line; Mr. Chen Yihan, General Manager of Haitian Hangzhou Sales Company; Mr. Chen Yirong, Regional Sales Manager; and Mr. Kuai Yue, Regional Manager of Haitian Smart Solutions. From Honsen Beverage Group, attendees included Mr. Jiang Chengming, Head of the Hangzhou Smart Pallet Project; Mr. Gong Yongbing, Production Section Chief of Guilin Plant; and Mr. Wu Ziwan, Production Section Chief of Tianjin Plant. Together, they witnessed the successful delivery of this important cooperation achievement.

Since the project was launched, both parties have attached great importance and worked closely together. The Hangzhou base took the lead, completing equipment delivery and commissioning on August 13, followed by the Tianjin and Guilin bases on September 1 and September 2 respectively. The smooth and efficient rollout across all three sites highlights Haitian’s outstanding integration capability and delivery efficiency.

This project was jointly executed by Haitian Plastics Machinery and Haitian Smart Solutions, delivering a comprehensive turnkey solution that covers both equipment and full plant planning. The delivered HA27000/peg turnkey projects are dedicated to the efficient production of pallets, integrating key modules such as automated part removal, precise block insertion, intelligent labeling, and high-speed palletizing, along with complete planning and implementation of utilities including water, electricity, and air. The result is a truly end-to-end solution that ensures rapid commissioning, stable operation, and a high level of integration, enabling Honsen Beverage to significantly enhance both efficiency and smart manufacturing capabilities.

The successful delivery across three sites demonstrated not only smooth production start-up and stable line performance but also validated the professionalism and forward-looking collaboration between the two companies. As the equipment supplier, Haitian Plastics Machinery leveraged its proven turnkey engineering expertise to provide Honsen Beverage with a fully integrated solution, facilitating the automation upgrade of its pallet production lines. Looking ahead, both parties will continue to focus on practical production needs, driving the industry toward greater efficiency and stability with reliable equipment performance and precise project execution, while offering a replicable model for future line upgrades.