Accurate exploration of local needs of the Vietnamese market

2023-07-13

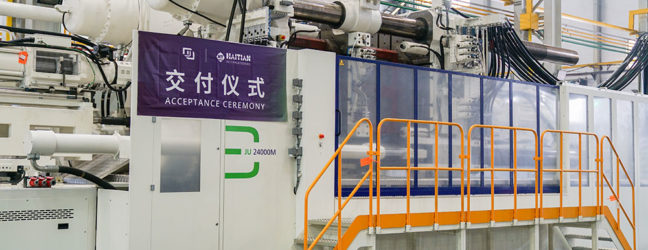

Vietnam Kai Guang Plastics Co. was established in 2008, located in Singapore Industrial Zone No. 2, Binh Duong Province, Vietnam, covering an area of 40,000 square meters, specializing in the development and production of various kinds of lotion pumps, ROLL-ON, bead bottles and other daily chemical packaging. The company now has a dust-free and constant temperature plant of 12,000 square meters, equipped with 99 sets of injection molding machines, 20 sets of ball making equipment, and 3 fully automated assembly lines for lotion pumps, ensuring 100% product testing of the production line.

Along with the accelerated economic recovery of Vietnam, more and more enterprises grasp the opportunity and set up factories in Vietnam. Recently, we had the honor of visiting Vietnam Kai Guang Plastics Co., to discuss the new market opportunities in Vietnam.

Haitian:Why did you choose to invest and build a factory in Vietnam?

Kai Guang Plastics: First, Vietnam’s tax incentives are an important factor attracting us to invest and establish a presence. Second, we provide support to numerous multinational companies, such as Unilever, Johnson & Johnson, and others. They all have factories in Southeast Asia, so there are a lot of synergies to invest here. Third, Southeast Asia is a very broad market, with immeasurable economic potential and market size, we hope to obtain greater development here.

Haitian:Your first machine was a Haitian injection molding machine?

Kai Guang Plastics: Our first injection molding machine was not Haitian. At that time, when we first came to invest, we directly transferred the old machines from China to use. Our company’s predecessor is a Taiwan factory, so initially, we used machines from Taiwan. But as time goes by our machines have been gradually replaced by Haitian machines.

Haitian:How did you get to know about Haitian in Vietnam?

Kai Guang Plastics: Haitian Vietnam has made investments in land acquisition and factory construction in Vietnam almost concurrently with us. Moreover, our proximity as neighbors cultivates a strong and intimate bond between our organizations. There are many companies come to Vietnam to invest, but there are not many companies like Haitian that can provide quality assurance and efficient after-sales service. In as little as 5 minutes after a phone call, Haitian’s after-sales service personnel will arrive and help us in the “last mile” of service. Haitian’s efficient after-sales service has become an important factor and stable anchor for our daily production, and injected more certainty for us to take root in Vietnam market.

Haitian:After years of use,what is your evaluation of our machines?

Kai Guang Plastics: We are very satisfied with Haitian. Especially noteworthy is Haitian’s profound understanding for local clients. Haitian has undertaken extensive localization explorations in the Vietnamese market, resulting in customized technological solutions and service experiences for us. One example: Haitian’s machine interface is available in Vietnamese, which our previous equipment supplier could not provide such a considerate service. In addition, Haitian’s machines are easy to work with the surrounding automation equipment, which can bring one-stop solutions.

Haitian:What is the current machine start-up rate?Is the production condition satisfactory?

Haitian:Do you have any outlook for the future?