Haitian Lighting Solution for the Automotive Industry – Efficient and Reliable Source of Light

2022-06-29

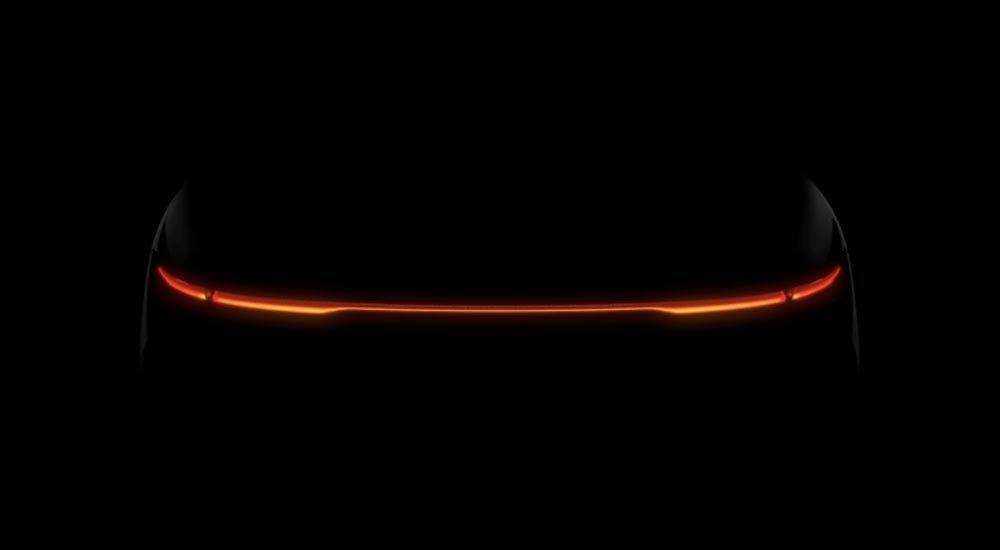

The electric vehicle market for passenger cars is growing quickly with increasing consumer demand. As a highlight of the electric vehicles, optical parts including long light guides have become a design trend in the automotive industry. Coming in many variations and with different visual effects, the lamps have tremendous design flexibility and also enhance the safety advantage.

Light guides: a high-tech product

The light guides – made of transparent plastics – is the light-emitting part of the car light. It has the advantages of high energy efficiency, a long lifespan, dimming capability, etc. It can effectively reduce the number of lamp bulbs and further achieve the goal of automotive light-weighting.

Technical challenges

Being an optical product, the manufacture of light guide strips for headlights has strict optical standards and appearance requirements. To meet the conditions like light transmission, thermal stability, shape accuracy, surface gloss, and haze, the material of the optical part issues high viscosity and moisture sensitivity as the disadvantages to overcome. Advanced injection molding technology during manufacturing, in other words, the stabilization of processing, is essential for those optical parts. Otherwise, defects may appear. It must also be mentioned that the suitable combination of the clamping and injection components is a predominant factor for the technical challenge caused by the thick mold and low filling volume.

Haitians’ Solution for Light Guides

In view of the characteristics and production difficulties of light guide strips, Haitians special machine solution can meet the production of long light guide strips (headlight guide, through-tail light guide, ambient light) and at the same time, can be compatible with other products to the greatest extent. Key components have been upgraded to reduce manufacturing risk.

Machines are equipped with PC special plasticizing components. Screw, barrel and other core parts are specially treated to meet the application requirements. Based on our Jupiter machine platform, the mold capacity and thickness have been increased.

The full closed-loop injection function helps low-speed injection molding and solves the problem of stability in low-speed condition. According to the physical laws of the light transmission, the plastics in the cavities of the thick-walled mold has to be not only filled continuously but also be smooth on the surface to make light transmission successful.

Long light guide

As a special optical part, the long light guide is lightweight with a length exceeding 1500mm. There have been several issues, such as the combination of clamping and injection components, plasticizing unit, and molding technology. It is generally believed that molding technology plays an important role which maintaining stability during the process based on the relevant tests and analysis.

So far, most vehicles on the road are equipped with LED lighting and light guides. With the popularity of vehicle intelligent driving technology, light guides will be more frequently used in the automotive exterior decoration. Haitian will continue to take customers and the market as the center, continue to empower the automotive industry, consolidate the core competitiveness of high-quality development, and jointly enter a new stage of development.