The medical market is exceptional in every respect, and it is changing rapidly. Hardly any other industry has gained such dynamic in recent times and has come under dramatic pressure – economically, logistically, in terms of delivery times – and not just since Corona. Reliability and consistency are extremely important right now, because the greatest possible efficiency and customized quality are the top priorities in this highly sensitive and highly stressed industry. Optimally designed for the required quality and productivity, cleanliness and precision. Technology to the point.

THE MEDICAL PACKAGE AT A GLANCE:

- Stainless steel hopper

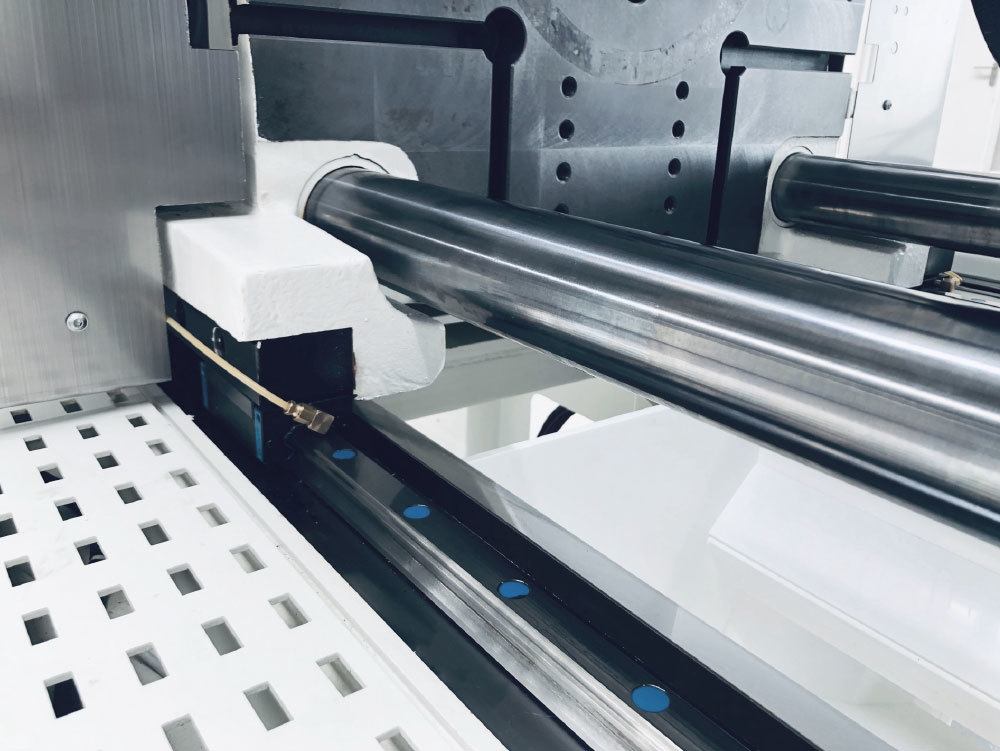

- Linear guides for moving platen

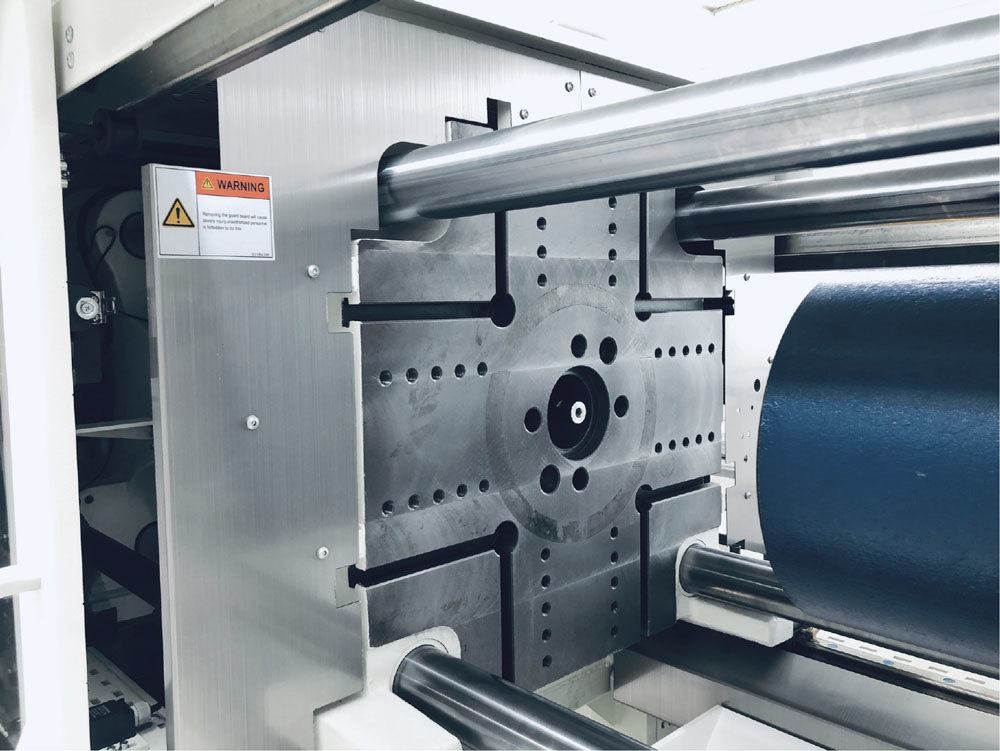

- Stainless steel cover around the moving platen

- Side sealing plate with mesh openings

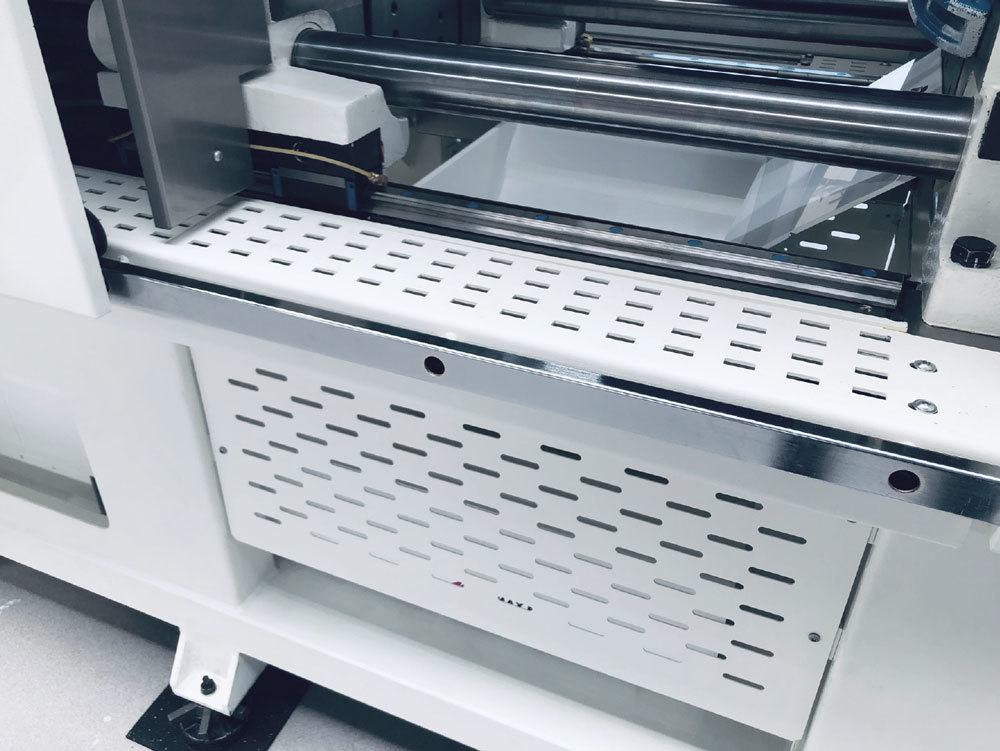

- Raised machine bed for better cleaning

- Stainless steel protective cover besides the ejection area

- Antistatic painting

The all-electric Venus Series combines system solutions for almost all medical application areas, from complex high-end applications in the small Series range to so-called “high volumes” with high cavities. From simple laminar flow box equipment to production in clean room environments. The Zeres Series is also becoming increasingly popular with our customers with medical applications. With its integrated hydraulics, the Zeres is optimal for molds with core pulls. It is mostly used when production takes place in the clean room.

Through cleanliness, documentation and precision, the Venus and Zeres “medical” Series not only meet the industry’s high production standards and strict regulations. Rather, the two Zhafir series bring a whole bundle of turnkey cleanroom solutions to the table and guarantee a fast time-to-market for their product. Because time is what counts these days!

1. Production and product quality well suited for medical products.

2. Anti-static painting and clamping structure to ensure cleanliness. Closed production space, machine layout according to medical industry standards.

3. Production management & information for traceability of production data and quality of medical products.

4. Higher production efficiency for high-cavity molds

Linear guides to support the moving platen. Stainless steel protection for smooth ejection of small parts.

No contact of the moving plate with the grease-free tie bars. Stainless steel protective cover around the moving platen prevents linear flow at the toggle.

Raised bottom of the basement for easy cleaning.

Sealing plates to divert laminar flows without turbulence.