MARKETS

AUTOMOTIVE INDUSTRY

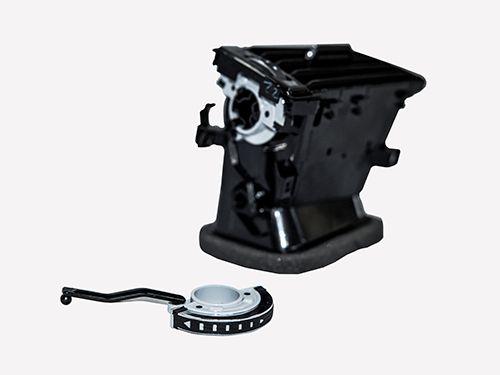

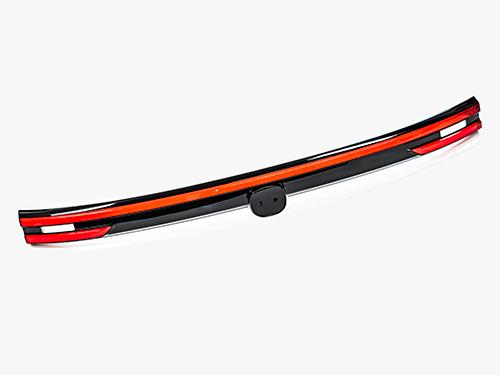

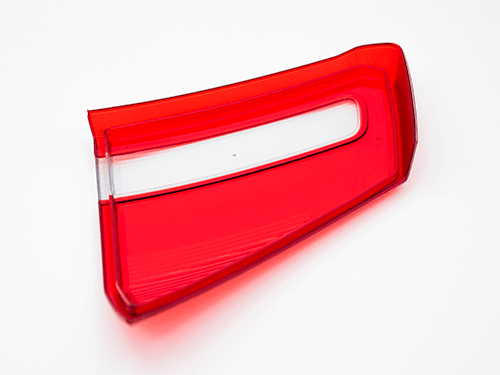

In its complexity, the automotive industry is probably the market with the widest range of applications. Visible parts for the interior, easy parts for power train, optical precision parts for the exterior, big parts like bumpers or cockpits and much more. Moreover, depending on the function of the parts, differentiated production solutions are required to meet the wide range of requirements, both on the product side and in upstream and downstream processing. Each product group has its own requirements regarding material homogeneity, surface quality, precision

Added to this is the diversity of applications through combinations of materials and processes (multi-component production, foaming, LSR, IML, IMD, etc.).

In view of this diversity of parts and production, T1-suppliers and their network are under increasing pressure. The quality requirements are enormous, product life cycles are becoming shorter and shorter and the price pressure is increasing.

CHALLENGES

THE CHANGING AUTOMOTIVE INDUSTRY

New requirements in terms of environmental protection will further fuel the cost spiral. And the deadline pressure for the processor will increase as the cost pressure is passed on to production and logistics. Moreover, futurologists see the automotive industry facing far-reaching changes. Alternative drives and autonomous driving will shape future visions of automotive culture.

What is needed is maximum flexibility on the machine side, coupled with productivity, top quality and new concepts for extremely economical and ecologically advantageous solutions. The tougher the competition, the more flexible the production portfolio in plastics processing should be. “Technology to the point” is extremely important in the automotive industry. Probably more important than in any other industry.

CUSTOMER STORY

Partnership Elevates Auto Parts Production

Partnership Elevates Auto Parts Production

2024-09-13

Valeo Group is a French industrial group specializing in the design, development, production, and sale of automotive parts, systems, and modules. As one of the world’s leading automotive parts suppliers, Valeo provides comprehensive solutions to all ma

Progress nonstop: Empowering the new era of E-Mobility

Progress nonstop: Empowering the new era of E-Mobility

2023-08-29

Currently, the wheels of history are spinning fast. From the era of fossil energy towards the era of new, sustainable energy, with a new round of industrial transformation accelerating its evolution. As a leading domestic supplier of automotive exterio

Haitian Multi Component Solution Rebuilding the value chain of the e-mobility industry

Haitian Multi Component Solution Rebuilding the value chain of the e-mobility industry

2023-04-01

US FARATHANE is a world-famous auto parts manufacturer, whose products are widely used in cars, consumer electronics, imaging equipment as well as various other industrial products. The company has production bases in Shanghai, Changchun and Taicang, w