Guangdong Blue Sky Plastic Products Co., Ltd. (Blue Sky) was founded in 1988 and is a professional manufacturer engaged in the research and development of plastic household daily necessities, mold manufacturing, injection molding, and sales. The company covers an area of over 67,000 square meters, with modern workshops of more than 100,000 square meters, modern loading and unloading platforms, an ultra-large raw material storage warehouse, and a large group of high-precision injection molding machines, as well as an intelligent unmanned production workshop. The company is committed to technological innovation and brand strategy development. With strong production capabilities and rich industry experience, it has now become a leader in the domestic household daily necessities industry.

02 First Witness ofNew Energy Efficiency and Productivity

As a long-term partner of Haitian, Blue Sky has had full confidence in the quality and technological innovation of Haitian’s products over the years. Therefore, when Haitian launched its fifth-generation technology, Blue Sky was quick to embrace this new technology with a forward-looking vision, opening a new chapter of energy efficiency and productivity.

Now, let’s join Yang Moulu, Assistant to the CEO of Blue Sky, to see how Blue Sky is leveraging these machines to achieve a win-win in production efficiency and environmental benefits.

02 A New BenchmarkThe Fifth-Generation TechnologyLeading Green Benefits

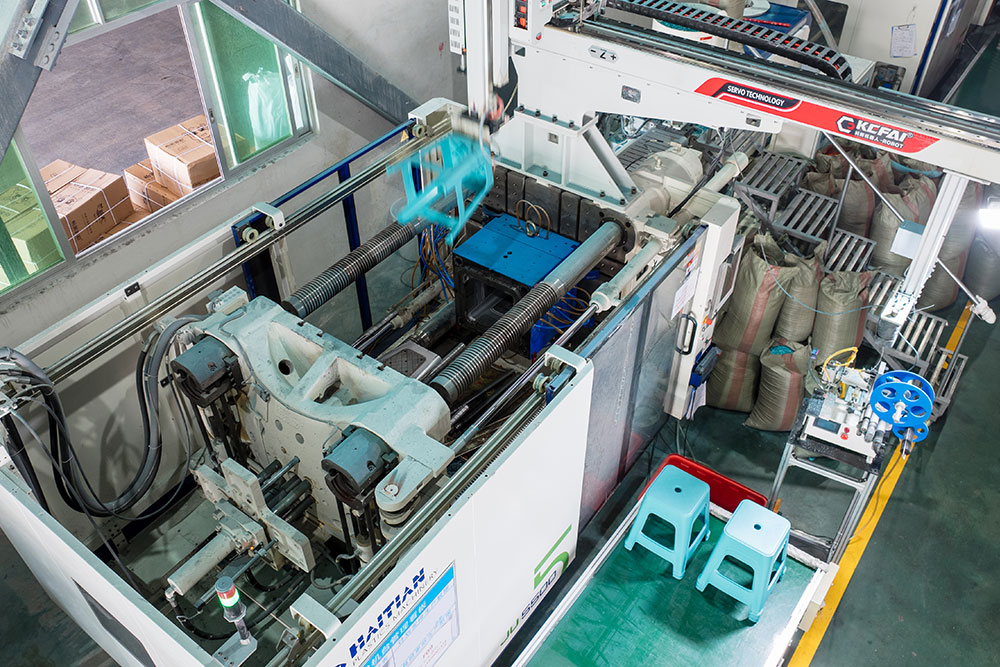

Upon entering Blue Sky’s workshop, 122 Haitian injection molding machines were lined up, working intensely and orderly. Each injection molding machine, with its excellent performance, demonstrates Blue Sky’s relentless pursuit of product quality and production efficiency. Among them, the newly introduced Haitian JU fifth-generation injection molding machines stand out. Under the efficient operation of the JU fifth-generation machines, chairs are precisely formed, smoothly demolded, and produced like flowing water.

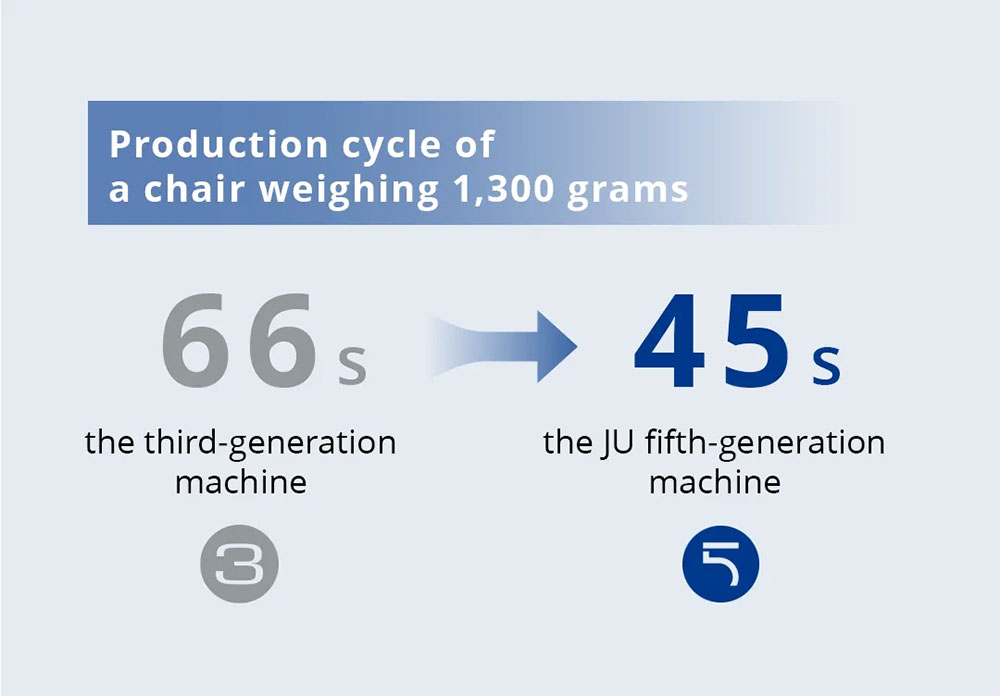

After a year of use and precise testing, Yang Moulu from Blue Sky told us, “For a chair weighing 1,300 grams, it used to take 66 seconds to produce with a third-generation machine, but the JU fifth-generation machine can achieve a production cycle of about45 seconds.”

This reduction of 21 seconds significantly improves production efficiency, showcasing the fifth-generation injection molding machine’s precise control over time costs and extreme pursuit, bringing substantial benefits to Blue Sky.

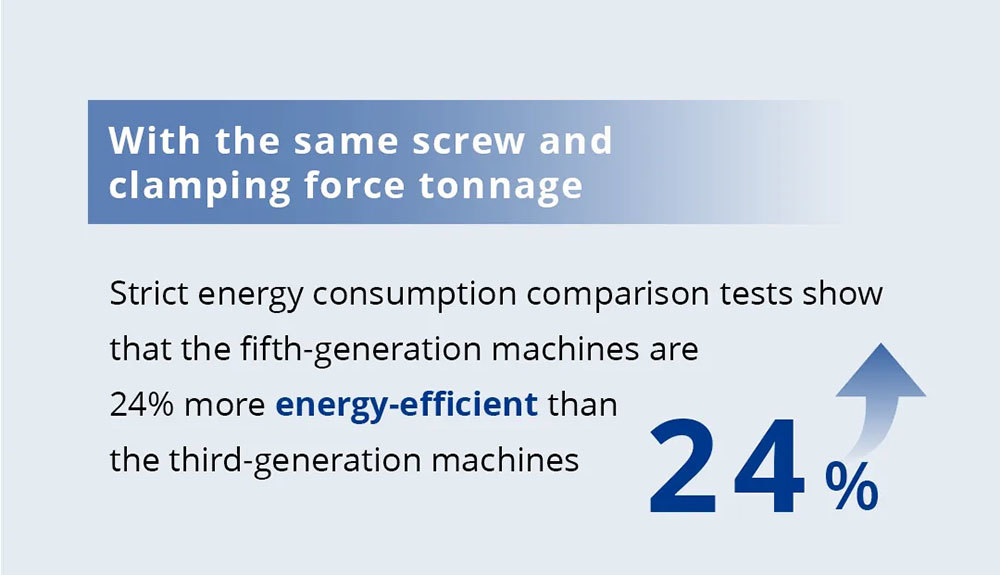

Equally impressive is the excellent energy-saving performance of Haitian’s fifth-generation injection molding machines. With the same screw and clamping force tonnage, strict energy consumption comparison tests show that the fifth-generation machines are 24% more energy-efficient than the third-generation machines. This figure is not only a leap in technology but also a responsibility and contribution to the environment.

03 HT·XTEN DA New Era of Production

In addition to significant efficiency and energy-saving effects, the HT·XTEND equipped on the fifth-generation injection molding machines has also brought unprecedented convenience to Blue Sky. Blue Sky’s frontline technicians can easily capture production data through the extensive intelligent functions with HT·XTEND, enabling fine analysis and scientific optimization, which is crucial for further improving production efficiency and product quality. Not only does this align with the development trends of modern manufacturing, but it also lays a solid foundation for Blue Sky’s long-term development.

Moreover, the fifth-generation injection molding machines from Haitian have also won Blue Sky’s favor with their outstanding stability and dsurability. During long-term operation tests, these machines consistently maintained a high-efficiency and stable working state, providing strong support for Blue Sky’s continuous production.

As one of the first users of Haitian’s fifth-generationinjection molding machines, Blue Sky is activelydemonstrating its relentless pursuit of quality and in-novation. The collaboration has not only brought significant improvements in production efficiency andcost savings to Blue Sky but set a new benchmark forthe entire industry.

Today, Blue Sky has fullyimplemented the use of Hai.tian’s fifth-generation injection molding machinesand has shared its successful experience with theentire industry. Looking ahead, we hope that Haitianand Blue Sky will continue to collaborate, exploringmore possibilities and jointly writing a new greenchapter of sustainable development.