Emission Management

Toxic Substances and Emission Management Policy

In strict accordance with the laws and regulations on waste discharge management and the Procedures for the Control over Solid Waste Discharge, we collect, sort and temporarily store wastes. Among our wastes, hazardous wastes mainly include sludge, waste emulsified mixture, paint residue, waste mineral oil, oily wastes, waste oil barrel, waste hydrochloric acid, waste carbon-based catalyst and waste filters, which will be handled by qualified contractors for harmless disposal. Non-hazardous wastes include packaging materials, metal scraps and other domestic garbage, among which, recyclable solid wastes will be handled by waste recyclers, and other domestic garbage will be regularly handled by the sanitation department.

We encourage all plants and functional units to reduce the wastes at source, actively explore solutions for waste recycling, and formulate plans for waste reduction, recycling and harmless disposal.

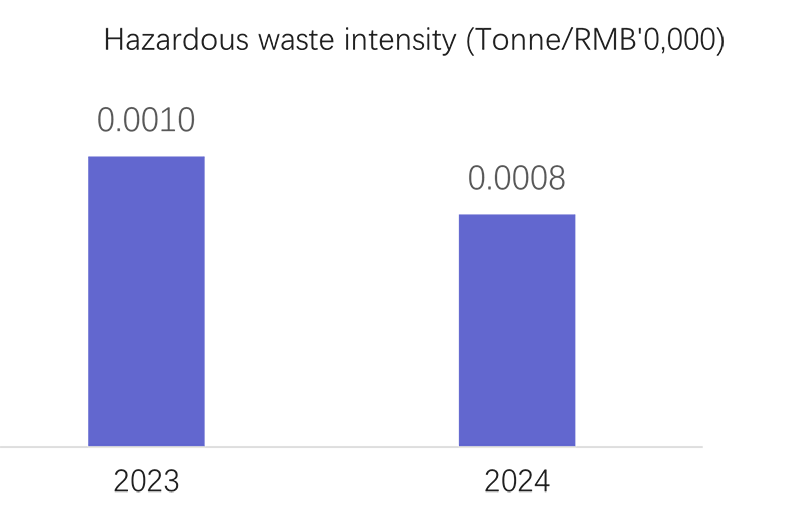

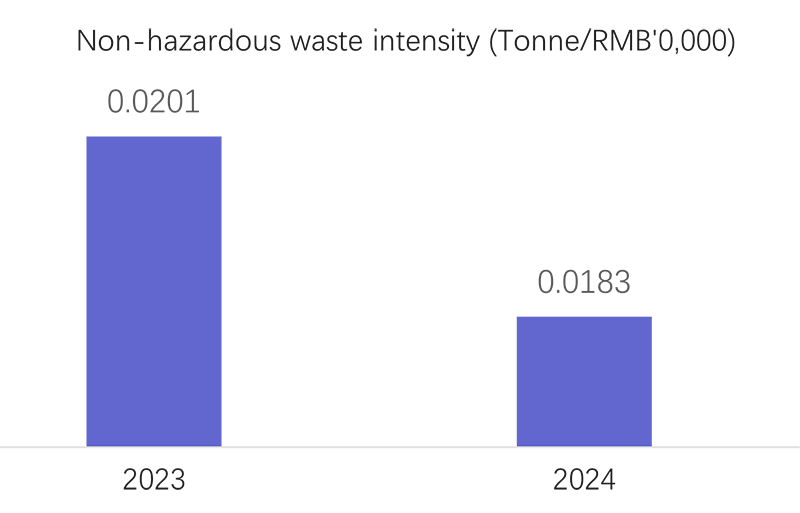

Performance of Toxic Substances and Emission Management

Note: The data only covers the plants in Ningbo, excluding the Wuxi Plant, Southern China Plant (under construction), and overseas plants; the intensity is calculated by the output per RMB 10,000 production value.

| 2023 | 2024 | % Change | ||

| Total hazardous wastes | Tonne | 1,359.92 | 1,330.49 | -2.2% |

| Total non-hazardous wastes | Tonne | 26,319.92 | 29,467.47 | 12% |

| Total hazardous wastes/Income during the year | Tonne/RMB10,000 revenue | 0.0010 | 0.0008 | -20% |

| Total non-hazardous wastes/Income during the year | Tonne/RMB10,000 revenue | 0.0201 | 0.0183 | -9% |

Emission Management (Waste Gas)

Policy of Waste Gas Emissions

In strict accordance with the laws and regulations on air pollution in the regions where we operate, we have formulated the Procedures for the Control over Waste Gas Emissions. Waste gas are qualified for emission standard after pollutants are treated by treatment facilities with process of capture and purification.

Performance of Waste Gas Emissions

| Waste Gas Emissions | Unit | 2023 | 2024 | % Change |

| NOx | kg | 756.85 | 709.27 | -6.3% |

Treatment Measures towards Waste Gas Emissions

For various waste gas emissions from operation, we take the following treatment measures:

| Category | Measures |

| Volatile Organic Compounds (VOCs) from painting | We use filters or hydro-spin to filter overspray, with filters replaced and paint residue removed from waste water containing overspray at regular intervals. In addition, we use carbon-based catalyst tanks to adsorb the filtered waste gases to meet the emission standard, and then emit them through an exhaust funnel with specified height. Saturated carbon-based catalyst will be desorbed at regular intervals, and pollutants desorbed will be discharged upon catalytic combustion. |

| Nitrogen oxides and particulate matters (PMs) from natural gas combustion | We use rotating precipitator and bag precipitator for standardised emission. |

| Dust from powdering process | We adopt two-layer treatment through cyclone precipitator for standardised emission. |

| PMs from polishing and shot blasting | We collect PMs through suspended hoods, and then treat them through cyclone precipitator and bag precipitator or Venturi scrubbers for standardised emission. |

| Chromic acid mist from electroplating | We use acid mist inhibitors to reduce the generation of chromic acid mist at source, and collect the mist produced through indraft for treatment with mesh chromic acid mist purifiers and pure water spraying. The treated waste gases are emitted through a 25m exhaust funnel. |

Emission Management (Waste Water)

Policy of Waste Water Discharge

We have formulated the Procedures for the Control over Waste Water Discharge, and built an in-plant waste water treatment station to treat the following production waste water by category: waste water from hydro-spin for paint overspray removing, waste water from the phosphating process, waste water from pre-treatment of the powdering process, waste water from site cleaning, as well as waste water from the electroplating process. The treatment station is equipped with an online monitoring system for waste water discharge, responsible for monitoring the quantity of waste water discharge, pH, chemical oxygen demand, the concentration of ammonia nitrogen, and others in real time. Waste water is discharged into the municipal waste water network after meeting the discharge standard. Domestic waste water from business activities is also discharged in compliance.

Waste water treatment and reuse measures

Rooftop treatment tank of the waste water treatment station