Shared Commitment to ROI, Smarter Way to Produce

2025-07-12

Founded in 1996, Jiangsu CITOTEST Labware Manufacturing Co., Ltd. (hereinafter referred to as “CITOTEST”) specializes in the R&D, manufacturing, and sales of laboratory equipment and consumables. Its product portfolio spans three main caFounded in 1996, Jiangsu CITOTEST Labware manufacturing Co., Ltd. (CITOTEST) specializes in the R&D, manufacturing, and sales of laboratory equipment and consumables. Its product portfolio spans histopathology, microbiology, and general lab supplies. CITOTEST exports to over 100 countries and regions—including the EU, North America, and Japan—and its domestic distribution network covers every province and municipality in China. The company is widely recognized by both professionals and distributors.

With more than two decades of expertise in the medical consumables industry, CITOTEST has followed a steady growth path. For them, success isn’t about high-end machines, while it’s about return on investment. On this journey, Zhafir electric injection molding machines have been a key partner for over ten years, supporting CITOTEST’s mission to deliver high-quality, precision medical products with Chinese-made equipment.

We recently spoke with Mr. Sun Li, Chairman of CITOTEST, to learn more about their story with Zhafir.

Back in 2012, CITOTEST was preparing to upgrade its production lines to manufacture thin-walled, transparent, and multi-cavity IVD consumables, demanding high levels of cleanliness. The older hydraulic machines struggled to meet these standards, and oil contamination posed a serious risk. “All-electric machines were like a myth in China back then,” recalls Mr. Sun. Though a German supplier offered a complete turnkey solution, the ROI projections didn’t hold up.

That’s when the Zhafir all-electric injection molding machine emerged as a game-changer. With its oil-free design, it addressed CITOTEST’ s core cleanliness requirements. Its precision control system met the stability needs for complex, high-cavity molding. More importantly, the localized service ensured cost-efficiency, faster response times, and reliable after-sales support.

The first two Zhafir machines immediate improvements in cleanliness and yield rates—marking the beginning of a long-term collaboration rooted in practical manufacturing value.

In 2020, demand for medical consumables surged. While others rushed for imported machines, CITOTEST once again turned to Zhafir. “To us, manufacturing is simple: quality first, but ROI matters just as much,” says Mr. Sun.

This mindset has fueled CITOTEST’s steady growth, with annual revenue approaching RMB 500 million. “Our cash flow is healthier than some public companies. ”And Zhafir’s cost-effective solutions have been instrumental in this success.

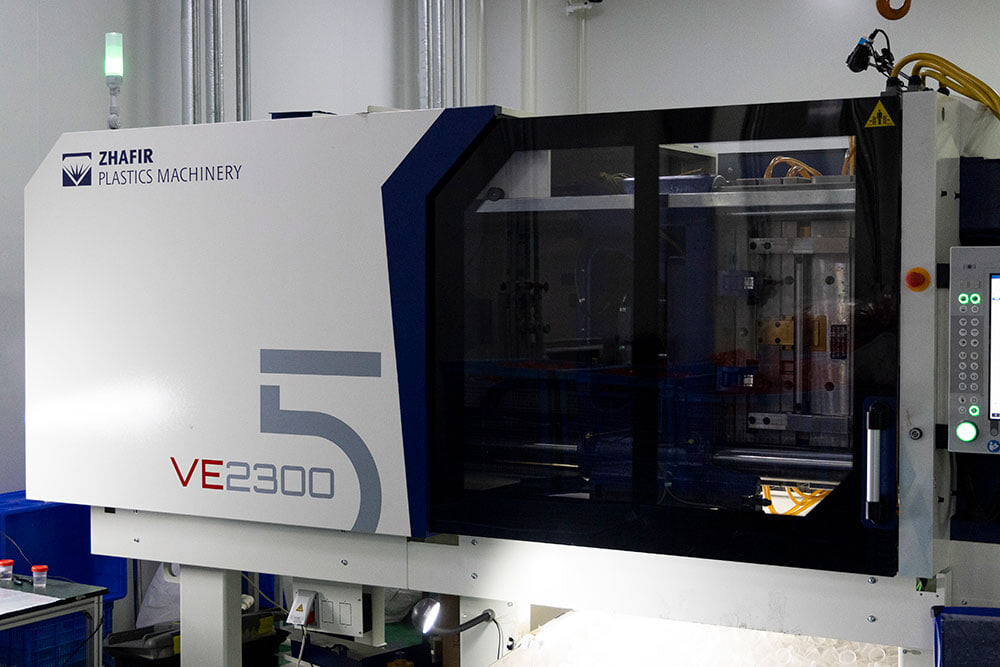

Today, CITOTEST operates over 30 Zhafir electric injection molding machines across its main production lines—running under high loads around the clock.

The first two all-electric injection molding machines successfully addressed CITOTEST’s cleanroom production challenges and improved product yield. This marked the beginning of a long-term partnership between the two companies. It’s fair to say that CITOTEST’s choice of Zhafir stemmed from a clear understanding of the true essence of production.

In 2020, demand for medical consumables surged. While many peers rushed to purchase imported equipment, CITOTEST remained committed to Zhafir—choosing value over hype. In Chairman Sun’s view, the rules of manufacturing have always been clear: “Quality comes first, but return on investment matters just as much.”

This pragmatic mindset has enabled CITOTEST to maintain steady growth, with annual revenue climbing to nearly 500 million RMB. “Our cash flow is healthier than many listed companies,” Chairman Sun remarked. “Competitors are often surprised when they see our financials during benchmarking.” Zhafir’s high cost-performance ratio has played a key role in supporting this strong and sustainable financial trajectory.

Today, CITOTEST operates over 30 Zhafir all-electric injection molding machines across its core medical consumables production lines, maintaining high-load operation on a daily basis.

Step into CITOTEST’s workshop and you’ll find precision-made medical consumables destined for over 100 countries. Behind these products lies a simple but powerful strategy: while others chase “top-tier” machines, CITOTEST has built a highly profitable, high-efficiency production system with 30 Zhafir electric injection molding machines.

Each start-up of a Zhafir machine is a vote for the value of “Technology to the point”. In the cleanliness-critical world of medical consumables, domestic solutions like Zhafir are proving to be essential, and they’re powering the future.