Haitian Medical Technology Center Open Day Concludes with Great Success

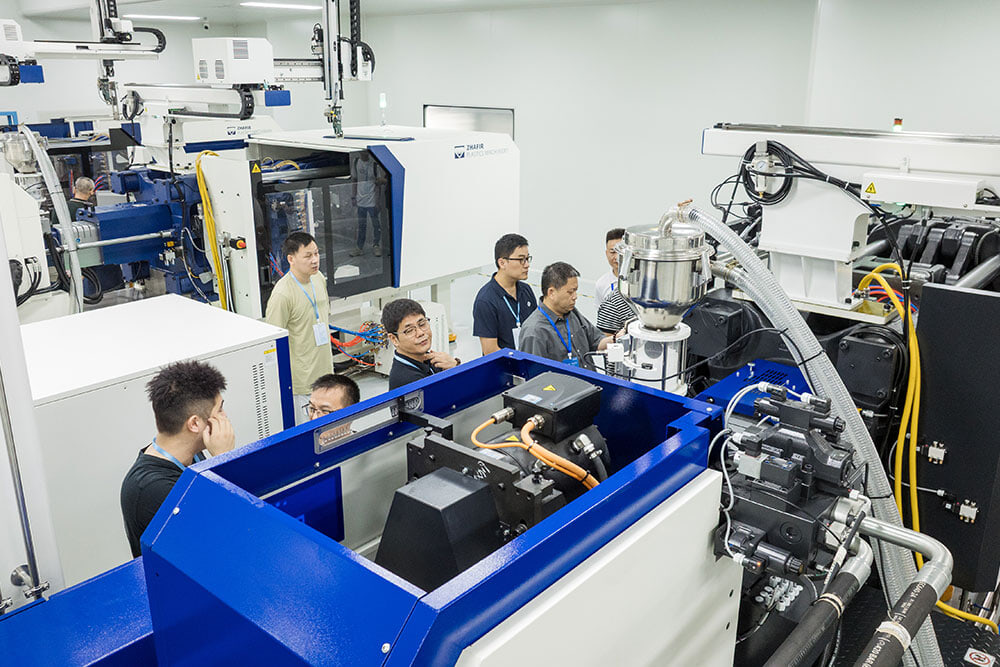

From August 1 to 2, the Haitian International Medical Industry Technology Center Open Day was successfully held in Suzhou, attracting over 200 industry experts, partners, and customer representatives. With the theme “Breaking Boundaries, Creating Value Together,” the event focused on technological innovation and collaborative applications in the field of medical injection molding. Through cutting-edge technology forums and live machine demonstrations, Haitian International showcased its high-end solutions for medical manufacturing.

At the beginning of the event, Mr. Zhu Hongguo, Director of the Medical Industry Division, delivered the opening speech. He welcomed all guests and shared insights on the technical challenges and collaboration opportunities in the medical sector.

Over the course of the two-day event, six thematic forums brought together cutting-edge topics in medical injection molding. In-depth discussions covered Haitian’s integrated PVC solutions for medical applications, the role of high-precision molds in emerging product trends, smart manufacturing solutions from Haitian Smart Solutions for the medical industry, the development outlook and market strategies in the insulin infusion sector, how RJG supports OEE improvement in medical injection molding, and how fundamental logic in polymer materials drives functional breakthroughs in medical applications. The sessions sparked active engagement and insightful questions from attendees.

At the event, Haitian International showcased eight precision injection molding solutions tailored for medical applications, covering the full spectrum of demands from micro components to large-scale devices. The demonstration area attracted a constant stream of visitors eager to observe the machines in action.

Notably, the fifth-generation Zhafir series features advanced precision molding technologies such as PDC (Precision Dosing Control), IFC (Inertial Filling Control), and OFC (Optimal Force Control). These innovations significantly enhance production stability and deliver outstanding performance in high-precision micro molding for medical applications, earning unanimous praise and recognition from attendees and industry experts alike.

Zhafir VE600V

Equipped with multi-cavity precision injection technology, this solution achieves 96-cavity molding of 0.02g PP protective caps with a cycle time under 20 seconds, meeting the demands of high-efficiency, large-scale production for miniature medical parts.

Zhafir VE900V

Utilizing micro-precision molding technology, this machine delivers stable 4-cavity production of 0.65g PBT insulin pen screw rods with a 15-second cycle time, addressing the high-precision requirements of small medical components.

Zhafir VE1200V

Powered by micro-precision molding technology, this solution completes 4-cavity molding of 2.8g PBT insulin pen plungers and barrels within an 18-second cycle, ensuring precision and efficiency.

Zhafir VE1500V

A specialized solution for medical-grade PVC, designed for 48-cavity production of 2.08g Y-type 3-way connectors used in blood transfusion sets. With a 20-second cycle time, it enhances the sealing performance of infusion systems while enabling high-throughput manufacturing.

Zhafir ZE1900V

With an 8+8 cavity design, this solution produces AS filter housings (top and bottom), each weighing just 2.5g, within a 20-second cycle—enabling precise and efficient matching for filtration devices.

Zhafir ZE2300V

Designed for high-efficiency multi-cavity molding, this system delivers 48-cavity production of 0.58g PP stop rings with a 10-second cycle time, meeting the demands of mass production for micro components.

Zhafir ZE3000V

Live on site, this machine demonstrated the molding of 32-cavity, 20ml syringe barrels using a full hot runner system with dual valve gates. Each part weighs 5.35g and is produced within a 12-second cycle, ensuring excellent precision and concentricity.

Haitian MA2100V/F

Featuring deep-cavity multi-cavity technology, this solution enables high-speed molding of 24-cavity, 1.96g PP syringe barrels in just 10 seconds, offering an optimal balance of performance and cost-efficiency.

This Open Day not only served as a platform for technical exchange within the industry, but also fostered full-spectrum engagement by seamlessly integrating expert discussions, solution showcases, and ecosystem collaboration. It highlighted the broader possibilities of medical injection molding technology.

Although the curtain has closed on the Open Day, the shared vision of “Breaking Boundaries, Creating Value” is now taking root as a new starting point for action. We look forward to seeing these solutions light up more customer production lines in the future. Driven by innovation, Haitian International will continue to join hands with its partners to push the boundaries of medical injection molding—transforming technological breakthroughs into real momentum for industry advancement.