Trend Rejlek

2016-10-07

PREPARED FOR EVERY EVENTUALITY

Trend Rejlek, a young subsidiary of Rejlek Metal & Plastics Group, primarily serves customers in the automotive and electric industry and has increased annual sales of 10 to 15% since the beginning.

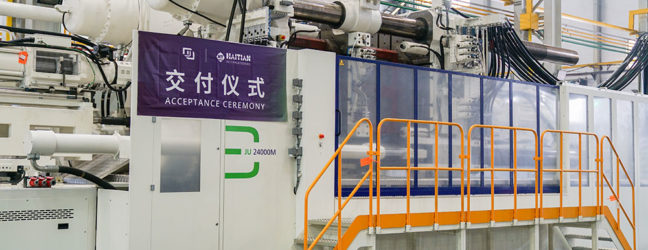

Trend Rejlek, a young subsidiary of Rejlek Metal & Plastics Group, primarily serves customers in the automotive and electric industry and has increased annual sales of 10 to 15% since the beginning. The biggest challenge as a supplier was to be able to react quickly to customer requests. For example, with versatile storage machines. The Trend Rejlek Ltd. was founded in 2008 at the location of Martin in Slovakia, as a joint venture of Rejlek Metal & Plastics Group and Trend Technologies Group, USA. Around 25% of yearly revenues Trend Rejlek generates through injection modeling – 18 machines from 800-5300 kN – including five fully electric models of the Zhafir Venus II series and two servo-hydraulic Haitian Mars series. We spoke on spot with the Managing Director Peter Lences.

“Trend Rejlek is still a young company which of course would like gain insight off of the experiences of its parent companies,” Lences admits openly. Nevertheless, he appreciates the opportunity to build up an autonomous company culture that is independent of the group. Currently, Trend Rejlek has 145 employees, divided into three layers throughout the 5-day work week. The atmosphere is relaxed even though there is work to do. “We have about four to five strategic key customers and other small customers for whom we carry out individual projects. This is a healthy mix and helps to make us quite stable. Our claim is to know the customer well enough to respond quickly to any changes in design or shape. So we equip the machine as best as possible so that we are prepared for all eventualities.” Automation inevitably occurs naturally due to rising labor costs. Even though flexibility is a big issue for Lences as well, for him it’s less about product life cycles – normally five to six years – but much more about the reaction strength with new inquiries. “The customer requests a project and expects that we can act immediately. It does not matter whether we have the right machine for this. And in turn the pressure is then passed onto the machine supplier”, he says smiling slyly. “Good for those who can offer reasonably flexible storage machines like Haitian International.”

Finally, we asked Lences what he would wish for the future of its equipment suppliers. “As I said, we get a project request from the customer, are responsible for the tool and ask our suppliers for the right machine. I may not always know what or if there is anything new, so I would like to rely on a comprehensive recommendation. Because sometimes we only have six to nine months of time. So why not maintain semi-mounted machines in storage, to then specify them with options according to the customer wishes? We agree. Warehouse equipment “to go”. That’s exactly what Haitian International Germany aspires. The capacity for this has already been created by the expansion of the site at Haitian International Germany.