From olympic to national Sport: The Story of a Badminton Manufacturer

2021-08-19

At the end of the Tokyo Olympics, the Chinese badminton team took first place in the medal standings of this competition with two gold and four silver medals. However, badminton in China is not only very successful at the professional level, but is also a popular sport for the general public. In addition to the bulk of badminton fans, China is also a leader in badminton manufacturing, with over 80% of badmintons being produced in China.

Recently, we had the pleasure of visiting the badminton manufacturing plant in Ningbo – Ningbo Donggang Sports Goods Co., Ltd. – and, accompanied by General Manager Shi Lei, further explored the badminton manufacturing process.

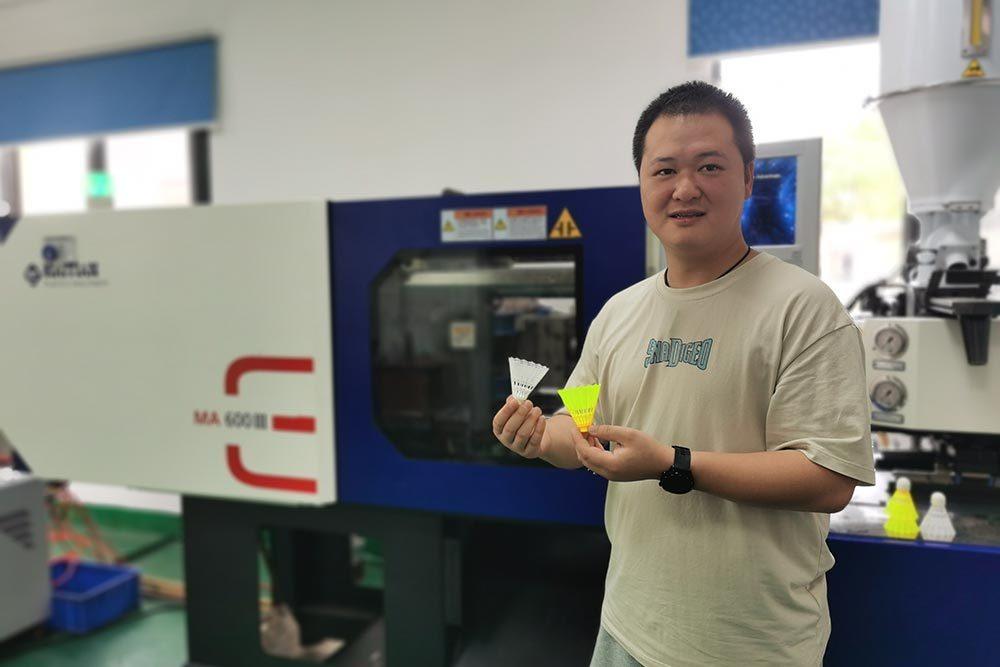

Shi Lei, general manager of Ningbo Donggang Sports Goods Co, Ltd.

Donggang Sports Goods was founded in 1981 and is mainly engaged in the development, manufacture and sale of badmintons for professional sports. In 2020, when the COVID-19 pandemic occurred, the market for badminton as an indoor sport was hit hard, and Donggang was no exception. In the aftermath, it was urgent for badminton manufacturers to face the challenges. With more than 40 years of experience in outdoor badminton, Donggang made the decision to develop a more professional outdoor nylon badminton.

Why Nylon Badmintons?

It takes more than 20 days to produce a natural badminton, while a nylon badminton can be produced in just one day in industrial production, and the durability of the latter is more than five times that of the former. In games, natural badmintons involve high cost and waste, and are mainly used for professional training and competitions.

Nylon badmintons are primarily considered for outdoor sports by replacing the natural springs with nylon. The badminton body is characterized by a precise one-piece design and should be manufactured with a single injection. The appearance, height, total weight, size and ball head of the nylon badminton match the natural shuttlecock. With stronger wind-breaking property and durability, it has become an overwhelming substitute for the natural badminton.

Nylon badminton from Donggang Sports Goods

According to Shi Lei, General Manager of Donggang Sports Goods, the plastic body of nylon badminton was designed according to the principles of aerodynamics and fluid mechanics to ensure the same flight performance and stability as natural badminton. The precise structural design of the body part requires high precision injection molding. The injection molded plastic body has a weight of only 3 g and a thickness of 0.3 mm, and the skirt consists of 16 thick stems and 16 curvatures, each with neatly arranged, precise holes. The temperature must not be too high or too low, because overheating would cause brittleness, hardening and even incrustation of the material, while underheating may result in short molding due to insufficient filling of the mold cavity.

Stability test of wind tunnel

Each manufactured nylon badminton is tested in a wind tunnel machine to check the flight stability. If the thickness deviation of the skirt spring blades is more than 0.02 mm, this will result in wobbly flight characteristics and the badminton must be rejected. Precision in the injection molding process as well as high repeatability is therefore the top priority.

Initially, Donggang used injection molding machines from other manufacturers. However, both the quality and the precision were not up to the mark and were far from the standard of a professional nylon badminton.

Zhafir Machine

High quality products require high quality production equipment. For the production of professional nylon badmintons, Shi Lei finally chose Zhafirs’ electric injection molding machines. „Zhafirs’ electric injection molding machines fully met the professional requirements of injection precision, efficiency and safety, and the apron injected by the machine is very clean and of high precision. According to the current technological parameters and test data, we have found that the cycle time has been reduced to less than 7 seconds and the productivity is close to 100% thanks to the injection speed of 350 mm/s. In addition, the amount of work required for assembly and testing after injection has been significantly reduced.”

Expansion of production with servo-hydraulic MA III Series.

In June this year Donggang Sports Goods bought an additional Haitian MAIII machine for production. “Our products are very demanding, and traditional hydraulic machines can hardly be used. It is amazing that the Haitian MAIII fulfilled the task excellently. The new generation Mars Series has key advantages. Haitian’s MAIII series is equipped with a high-power servo drive system, which, combined with the brand new motion control and digital bus technology, provides high dynamic response, ensuring the quality of precision products.

More about Badminton

For easy training and daily fitness and entertainment, nylon badminton is more durable and economical, so amateurs with limited budget can enjoy the sport more. In Southeast Asia and Europe, professional nylon badminton has taken a firm place in the daily sports of badminton enthusiasts.

With the popularization of the national sports program in our country, professional nylon badminton will bring more cost-effective outdoor sports plans to the masses and promote the game of badminton from the competitive field of the Olympic Games to outdoor courts for national fitness sports. We believe that nylon badminton will have a wider and wider market in the future, and the professional sporting goods made in China will be recognized in more and more international markets.

*Some of the pictures in this article come from the Internet. If there is infringement, please contact us for deletion.